Your Ultimate Trail Companion

135/140mm

Rear/Front Suspension

Introducing the all-new Cascade Peak

The Cascade Peak is our latest addition to the Ari mountain bike family – an aluminum full suspension mountain bike designed to redefine your trail riding experience. This do-it-all trail bike is engineered to tackle a wide range of riding disciplines and situations, offering a balanced and easy-to-handle ride.

Take Your Riding to the Next Level

65° Headtube

20mm Reach Increase

78° Seat Tube

We've redefined the Cascade Peak's geometry for optimal performance. With a slacker headtube angle at 65 degrees and a steeper seat tube at 78 degrees, descending is more stable and your pedaling becomes more powerful and efficient. The increased reach, averaging 20mm more, ensures enhanced comfort in the cockpit and superior handling on varied terrain.

Better Suspension Kinematics for Stability and Traction

Featuring 135mm rear and 140mm front suspension travel, the Cascade Peak boasts improved suspension kinematics with our Tetra-Link Suspension design. Experience superior stability and traction while climbing and descending thanks to enhanced anti-squat and anti-rise tuning.

Elevate your riding experience

on our newest all-mountain trail bike.

Crafted for Strength and Weight Savings

The Cascade Peak's aluminum airformed and hydroformed custom butted tubes are strategically thickened at weld points for strength and thinned where unnecessary, resulting in a 250-gram weight reduction compared to traditional straight-gauge tubing. The frame is both robust and lightweight.

Upgraded Features for Enhanced Performance

Benefit from a lower standover height, offering more clearance and accommodating longer dropper seatposts. Custom molded rubber protectors minimize chain slap noise, and an epoxy-infused paint adds strength while resisting chips and scratches.

Convenient Maintenance and Lifetime Warranty

The Cascade Peak is UDH compatible for easy maintenance and service. As with all Ari bikes, enjoy the confidence of our Lifetime Warranty on the frame. Choose from a variety of robust 1x drivetrains, powerful hydraulic disc brakes, and best-in-class suspension options for a customized riding experience.

GA-Link for Personalized Adjustments

Experience unparalleled customization with the GA-Link. Now located in the rocker-link for increased rear triangle stiffness. Adjust head tube angle and bottom bracket height effortlessly and adapt to your trails. Optimized for 29er and mullet wheelset compatible, the Cascade Peak is your ticket to fun on the trails.

Go ahead, take it for a spin.

Evolved Geometry

We've transformed the geometry of the Cascade Peak for unparalleled performance.

"The Ari Cascade Peak Elite is a welcome new offering to the budget full suspension mountain bike space, offering impressive quality for its price tag and solid on-trail performance to go with it."

"With new buyers, the brand will go through an extensive fit process before sending the bike so that it’s ready to rock."

"Ari has stuck to its focus on delivering a lot of value to riders without resorting to common cost-cutting measures."

"Ari has established itself as making some pretty darn good bikes, sticking to a consumer direct model, and are also extremely affordable."

"I realized how deeply in touch Ari is with what riders want and what the industry needs."

"The geometry is ... revolutionary."

"The brand relies heavily on its customer support reputation, and also offers a 30-day "Love It Or Return It" trial period and a limited lifetime warranty on all its products."

"Ari has smashed one deep into the bleachers."

Cascade Mountain Range

40.3072° N, 111.5888° W

Cascade Mountain is located in central Utah. With an elevation of 10,908 feet it towers over Utah County where Ari HQ is located. To the north is Mount Timpanogos and Provo Peak to the south, Cascade is one of the major peaks of the Wasatch Range. The Cascade Peak is designed to tackle rough and rugged terrain both up and downhill for those that want something to do it all.

Save up to 40% Buying Direct

Bigger savings and perfect fit.

We sell directly to you- the rider. This gives you unique advantages like getting your Cascade Peak custom fit to your body measurements, big savings on cost, and direct communication with us.

Lifetime Warranty

A warranty that lasts a lifetime.

We tested the Cascade Peak 130% above industry standards. We want you to ride with the peace of mind knowing that this bike performs at an elite level, always. Your bike comes backed with a Lifetime Warranty. Ride it on your own trails for 30 days and if it’s not the best bike you’ve ridden, you can return it.

Geometry

Units

| S | M | L | XL | |

|---|---|---|---|---|

| Top Tube | 560 | 593 | 613 | 637 |

| Seat Tube | 400 | 420 | 440 | 460 |

| Chainstay | 434 | 434 | 434 | 434 |

| Head Angle | 65° | 65° | 65° | 65° |

| Seat Angle (Effective)* | 78° | 78° | 78° | 78° |

| Head Tube | 95 | 95 | 115 | 130 |

| Bottom Bracket Height | 345 | 345 | 345 | 345 |

| Bottom Bracket Drop | 28 | 28 | 28 | 28 |

| Wheelbase | 1180.8 | 1205.8 | 1239.2 | 1265.5 |

| Fork Offset | 44 | 44 | 44 | 44 |

| Standover Height | 734 | 741 | 751 | 763 |

| Stack | 604.0 | 603.9 | 622.0 | 636.0 |

| Reach | 430 | 455 | 480 | 500 |

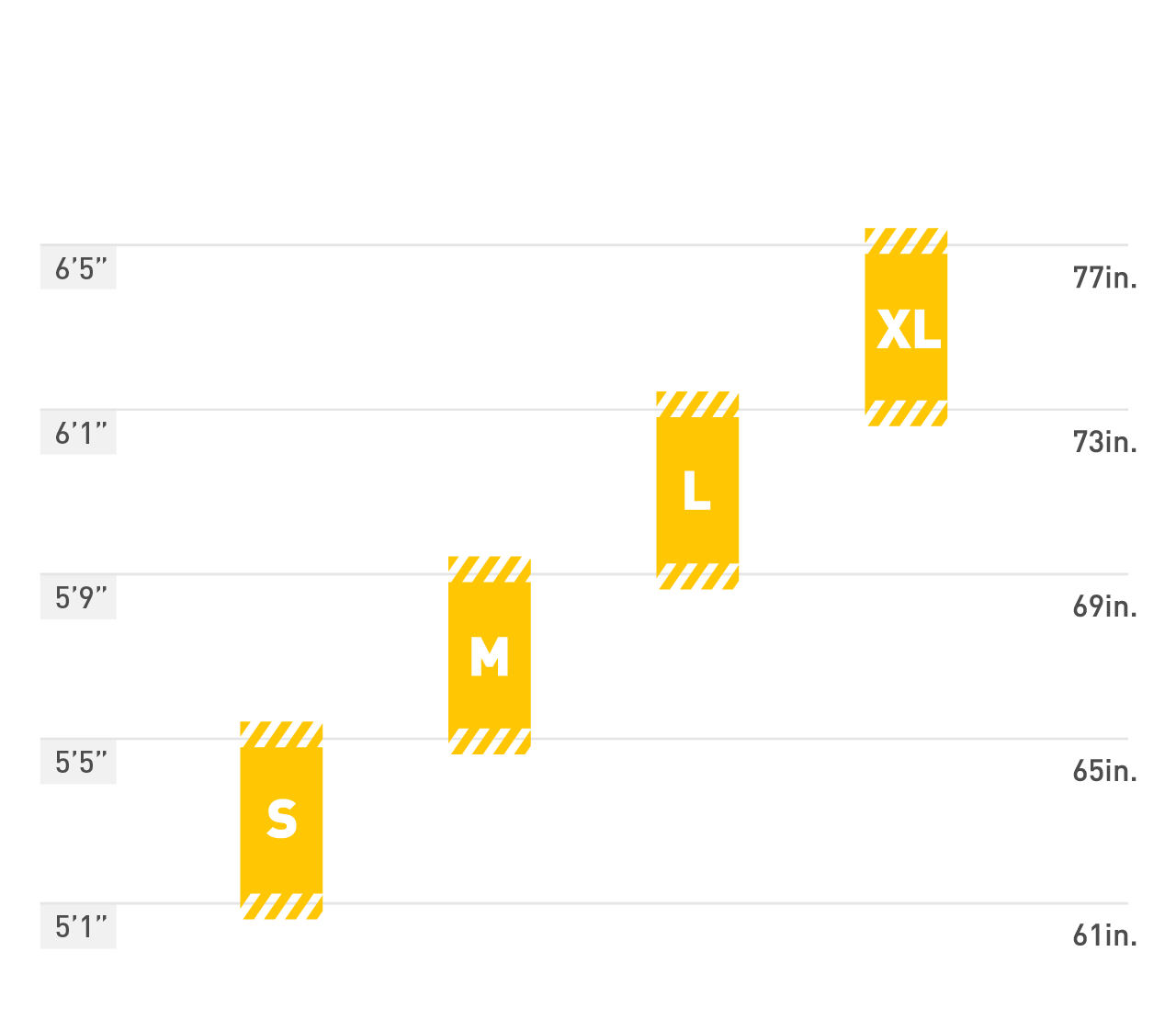

What’s my frame size?

Your height will determine a general recommended frame size. Occasionally, based on other body measurements, you may feel more comfortable on a different size. We recommend completing the 23-Point Custom Setup when completing your order.

Recommend a frame size for meBuild Specs

Each Ari bike is built with the best components in a given category so you get the most bang for the buck. Each model has different build specs to choose from usually ranging in good, better, best order.

Comparison TableBuild Level

*Specs are subject to change. Any substitutions will be comparable or better.