The Empire is the do-it-all road bike.

20.5%

Lateral Stiffness

Efficient Power Transfer

Empire has evolved from our previous gen road bike. Experience a 20.5% better head tube lateral stiffness allowing more confident cornering and better sprinting power. Ride with 15.3% more efficient rear wheel power transfer and a 3% stiffer bottom bracket. Efficiency = Power.

Damping Construction

860 Grams

UCI Certification

Because of Monoform™ construction, vertical flexing seat stays, and 27.2mm seat posts, high speed road vibration is significantly reduced, making it the most comfortable road bike you’ll ride.

An Adaptable Ride

Get tires up to 32c, which means more comfortable rides on all road conditions, and up to 3 cages in the front triangle for more hydration or your tool kit.

King of the Road.

Full Carbon & Endurance Design.

Strength through technology.

By using Monoform™ construction – a true 1-piece mold – there is no bonding, no dead spots, and no frame alignment issues. The Empire even passed XC mountain bike standards during testing.

Beautiful on the inside and out.

CleanCast™ manufacturing results in carbon walls that are consistently uniform, free from joints, creases, excess resin, and wasted material.

Keeping it simple.

By streamlining the conventional manufacturing process, we have significantly decreased the likelihood of errors. There's no need for pre-bond machining since there's no bonding required. The absence of bonding eliminates the necessity for bond curing. Additionally, secondary alignments are no longer needed. As a result, we achieve enhanced frame strength and consistency.

Weightless Innovation

The Empire is our lightest bike with a frame weight starting at an incredibly low 815 grams. It's fork starts at 392 grams. Light and strong, the Empire will get you KOM in no time!

Go ahead, take it for a spin.

Full Carbon & Endurance Design

"The Empire SL will leave you happily exploring for endless miles."

"I was unable to feel any downside compared to competitors’ bikes costing thousands more."

"Given the lightweight Monoform construction, we think the pricing is more than justified if that is the range you are going after."

"Thoughtful details like full internal cable routing and 32mm tire clearance make the Empire a legit contender..."

"The Empire SL Team Edition Shimano features a premium carbon fiber frame and components that make the entire bike very light and easy to handle and accelerate.

"With new buyers, the brand will go through an extensive fit process before sending the bike so that it’s ready to rock."

"I realized how deeply in touch Ari is with what riders want and what the industry needs."

"As you go to purchase your next bike, I encourage you to give Ari a look."

Empire Pass

3,248ft Elevation Gain

Renowned for its challenging nature, the southern approach to Empire Pass stands out as one of Utah's toughest climbs. Notably, it has hosted professional cyclists during events like the 2012 Tour of Utah, when it was also utilized for the ascent.

Save up to 40% Buying Direct

Bigger savings and perfect fit.

We sell directly to you, the rider. This gives you unique advantages like getting your Empire custom fit to your body measurements, big savings on cost, and direct communication with us.

Lifetime Warranty

A warranty that lasts a lifetime.

We tested the Empire 130% above industry standards. We want you to ride with the peace of mind knowing that this bike performs at an elite level, always. Your bike comes backed with a Lifetime Warranty. Ride it on your own trials for 30 days and if it’s not the best bike you’ve ridden, you can return it.

Geometry

Wheel Size

Units

| XS | S | M | L | XL | |

|---|---|---|---|---|---|

| Top Tube | 510 | 530 | 550 | 570 | 590 |

| Seat Tube | 452 | 482 | 513 | 541 | 564 |

| Chainstay | 410 | 410 | 410 | 410 | 410 |

| Head Angle | 71° | 71° | 71° | 71° | 71° |

| Seat Angle | 75° | 74.5° | 74.5° | 73.5° | 73.5° |

| Head Tube | 115 | 130 | 160 | 180 | 200 |

| Bottom Bracket Height | 271 | 271 | 271 | 271 | 271 |

| Bottom Bracket Drop | 72 | 72 | 72 | 72 | 62 |

| Wheelbase | 975 | 990 | 1002 | 1014 | 1024 |

| Fork Offset | 45 | 45 | 45 | 45 | 45 |

| Standover height | 726 | 751 | 776 | 810 | 829 |

| Stack | 518 | 533 | 563 | 582 | 603 |

| Reach | 371 | 382 | 388 | 397 | 405 |

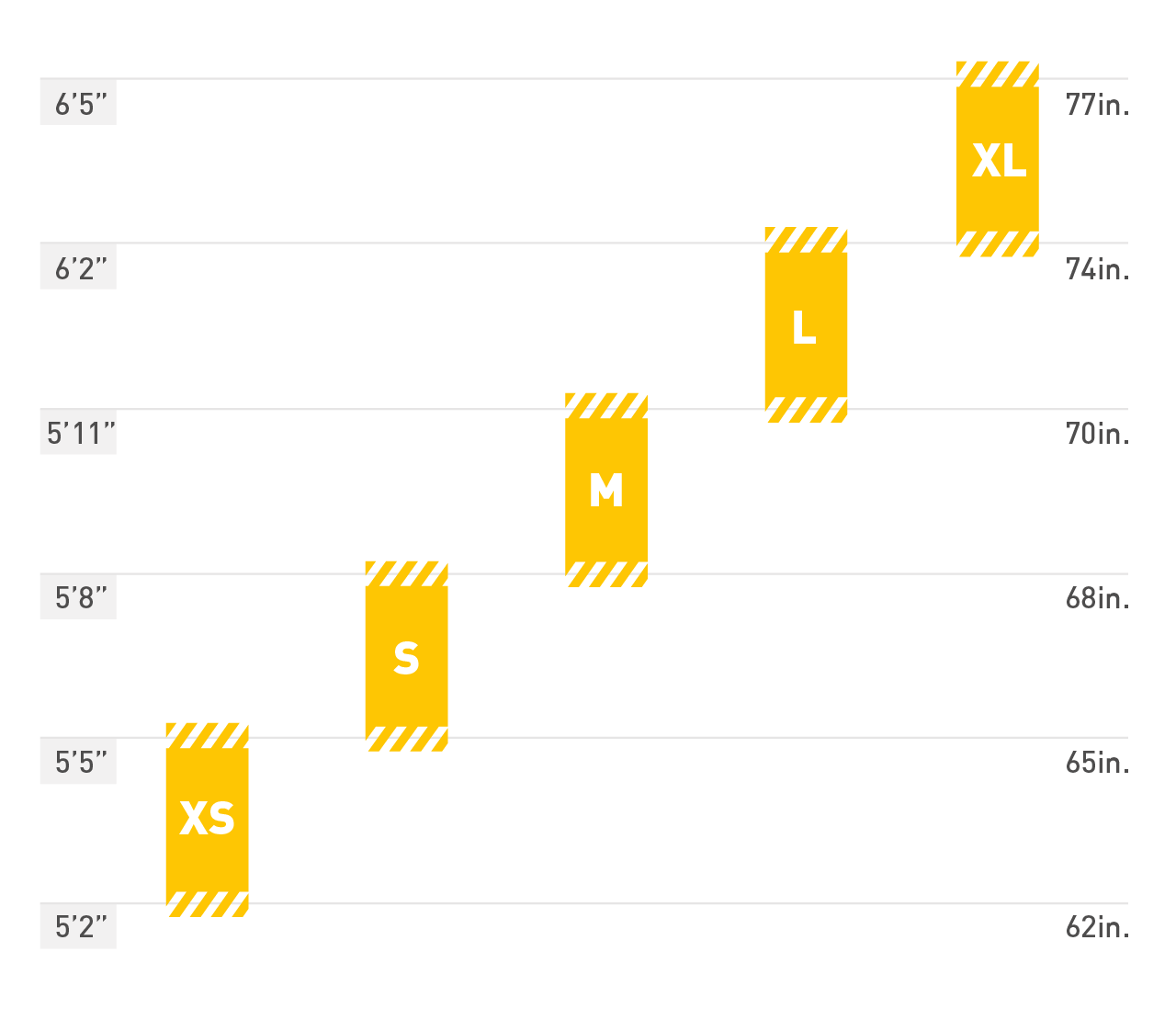

What’s my frame size?

Your height will determine a general recommended frame size. Occasionally, based on other body measurements, you may feel more comfortable on a different size. We recommend completing the 23-Point Custom Setup when completing your order.

Recommend a frame size for meBuild Specs

Each Ari bike is built with the best components in a given category so you get the most bang for the buck. Each model has different build specs to choose from usually ranging in good, better, best order.

Comparison TableBuild Level

*Specs are subject to change. Any substitutions will be comparable or better.