Perfect balance of racing and fun.

68°

Head Tube Angle

A true game changer.

The 68-degree head tube angle adds confidence and stability in rough terrain and agility while cornering. The steep 75-degree seat tube angle helps put your body in a powerful and efficient pedaling position.

Wheels for any trail.

29er

27.5+

Capable of running 29er or 27.5+ wheel size. This allows riders to explore more than in comfort and confidence with the wide 2.8 plus tires, or tow the race line with the fast and efficient 29er setup.

Value that exceeds its price point.

Lightweight and strong, our aluminum alloy frames comes with internal cable routing with removable service ports to keep things tidy. Like all Fezzari frames the Wasatch comes with our Lifetime Warranty.

Value, versatility, and fun.

The ultimate hardtail mountain bike.

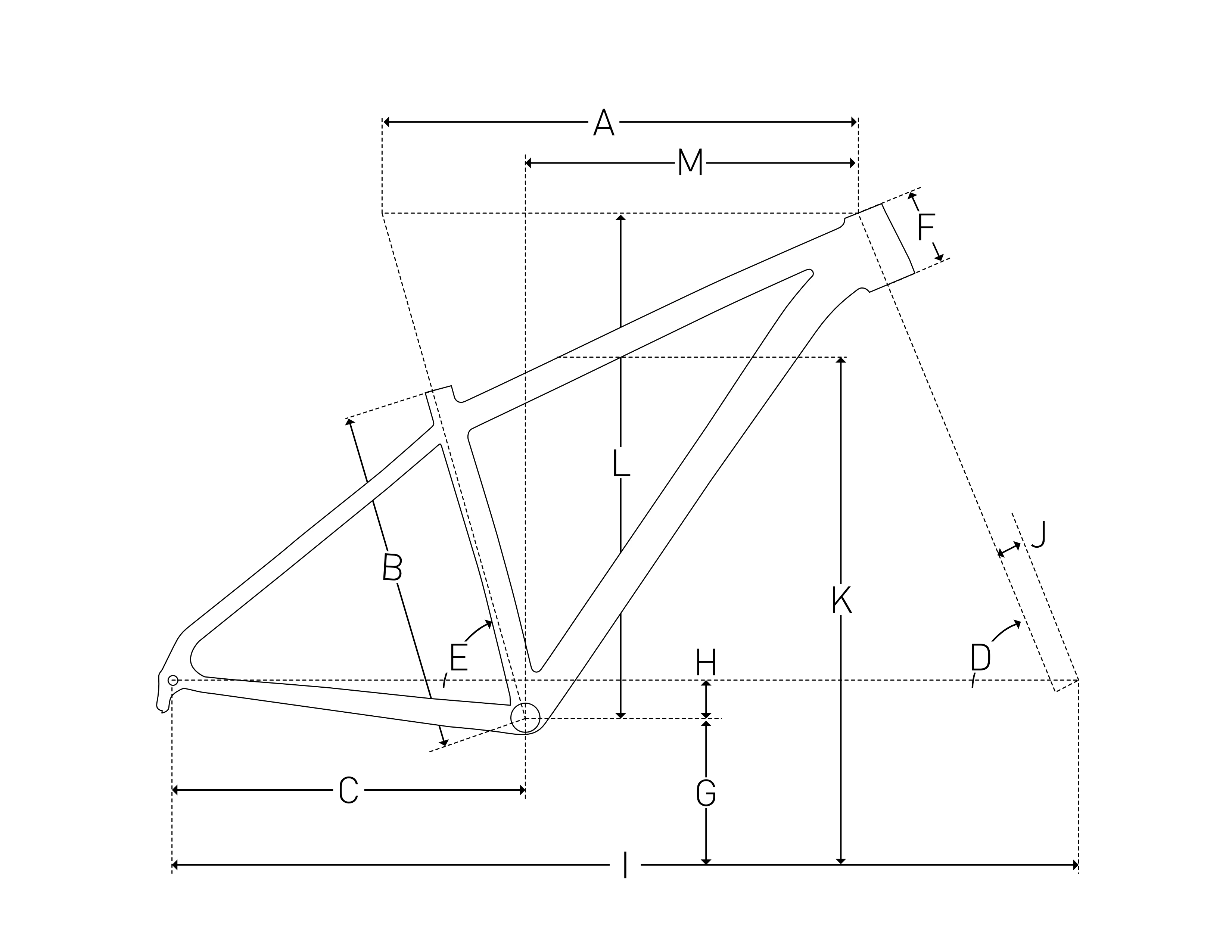

Geometry

Wheel Size

Units

| S | M | L | XL | |

|---|---|---|---|---|

| Top Tube | 559 | 582 | 609 | 634 |

| Seat Tube | 381 | 430 | 483 | 533 |

| Chainstay | 435 | 435 | 435 | 435 |

| Head Angle | 68° | 68° | 68° | 68° |

| Seat Angle (Effective)* | 75° | 75° | 75° | 75° |

| Head Tube | 95 | 95 | 110 | 125 |

| Bottom Bracket Height | 315 | 315 | 315 | 315 |

| Bottom Bracket Drop | 60 | 60 | 60 | 60 |

| Wheelbase | 1103 | 1127 | 1155 | 1155 |

| Fork Offset | 51 | 51 | 51 | 51 |

| Standover Height | 775 | 782 | 786 | 790 |

| Stack | 613 | 613 | 627 | 641 |

| Reach | 395 | 418 | 441 | 462 |

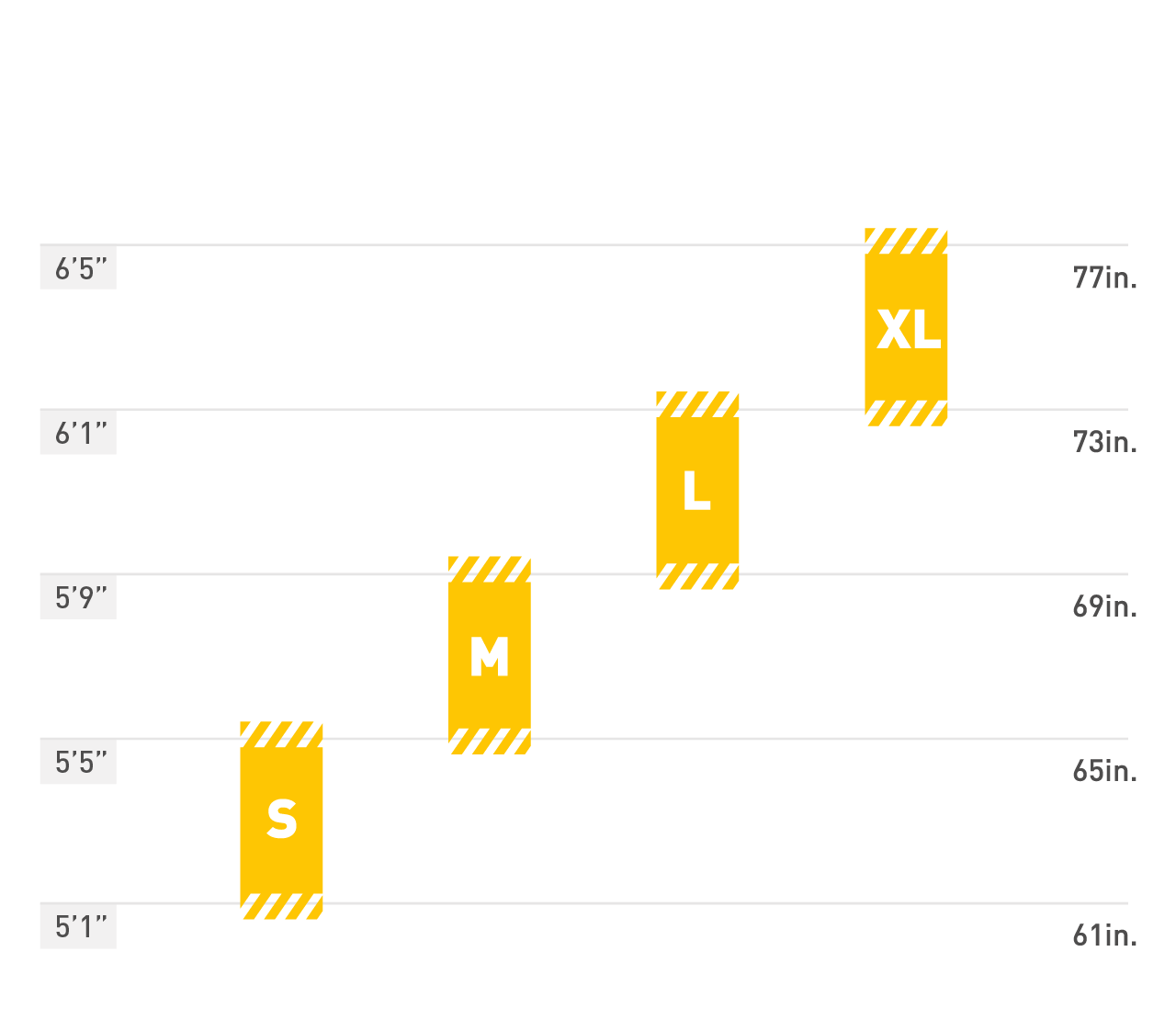

What’s my frame size?

Your height will determine a general recommended frame size. Occasionally, based on other body measurements, you may feel more comfortable on a different size. We recommend completing the 23-Point Custom Setup when completing your order.

Recommend a frame size for meBuild Specs

Each Ari bike is built with the best components in a given category so you get the most bang for the buck. Each model has different build specs to choose from usually ranging in good, better, best order.

Comparison TableBuild Level

*Specs are subject to change. Any substitutions will be comparable or better.